2-Way Pallet Shuttle System Deep Dive: Maximizing Warehouse Storage Density with Minimal Space

The demands of modern e-commerce and fast-moving consumer goods (FMCG) have pushed warehousing logistics to its limits. Traditional racking systems often sacrifice density for accessibility, leaving significant unutilized space. The solution? The 2-Way Pallet Shuttle system—a semi-automated, high-density storage breakthrough.

What exactly is this technology? It is an autonomous, battery-powered cart designed to travel on dedicated rails within deep-lane racking channels, moving pallets for storage and retrieval operations in two directions (forward and backward).

This article provides an expert analysis of the system, detailing its technical components, strategic advantages, a critical ROI model, and real-world applicability to help you make informed investment decisions.

1. How the 2-Way Pallet Shuttle Mechanism Achieves Deep-Lane Automation

The genius of this shuttle technology lies in its simplicity and efficiency. It eliminates the need for forklifts to enter the deep aisles, a process that accounts for significant time loss and risk in conventional drive-in systems.

1.1 Key Components of the 2-Way Pallet Shuttle Ecosystem

- The Shuttle Car: This is the heart of the system. Powered by advanced batteries, the shuttle uses onboard sensors to precisely lift, place, and move pallets. Its robust design ensures continuous operation, even in challenging environments.

- Dedicated Racking & Rails: The system requires specialized, deep-lane racking engineered to support the shuttle and guide its movement. The depth of these channels is often the factor that yields massive space savings.

- Control System: Operators manage the shuttle via a simple remote control or integrate it with a Warehouse Management System (WMS) for more complex, automated sequencing.

1.2 Operational Modes: LIFO vs. FIFO Flexibility

- LIFO (Last-In, First-Out): The most common application, where loading and unloading occur from the same side of the rack. This is ideal for buffer storage or goods with long shelf lives.

- FIFO (First-In, First-Out): Achieved by loading from one side of the deep lane and retrieving from the opposite side.

💡 Deep Dive: Addressing the ‘Last Meter’ Efficiency Bottleneck

While the 2-Way Pallet Shuttle moves rapidly within the lane, true system efficiency often boils down to the throughput rate at the aisle entrance. The system is considered semi-automated because a forklift operator is still required to place the shuttle and pallet into the entry position and retrieve them. Therefore, maximizing the forklift’s utilization and minimizing idle time at the front of the rack is the true determinant of overall logistical success. (4)

2. The Strategic Case for the 2-Way Pallet Shuttle: A Critical ROI Analysis

The decision to invest in this technology is fundamentally a strategic one, focused on long-term resource optimization.

2.1 Maximizing Space Utilization: The Financial Impact of Density

By drastically reducing the required number of aisles—which are essentially non-storage space—the system can boost storage density by up to 80% compared to selective racking.

From the strategic vantage point of a leading enterprise operator, the acquisition of a 2-Way Pallet Shuttle system must be viewed not merely as capital expenditure, but as a strategic investment in both “land and time.” When the system elevates storage density by eliminating non-productive aisles, it is, in essence, creating new usable square footage. This increase in efficiency is significantly more cost-effective than leasing or constructing new facilities. Therefore, the core metric for evaluating this system is its ability to rapidly increase Tonnage Throughput and accelerate capital turnover—a clear foundation for sustainable business growth.

2.2 Quantifying the Value: Simplified ROI Calculation Model

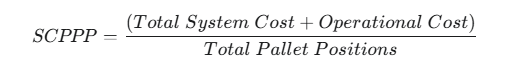

To make the benefits tangible, consider a simplified model comparing Storage Cost Per Pallet Position (SCPPP):

SCPPP = (Total System Cost + Operational Cost)/Total Pallet Positions

By dramatically increasing the Total Pallet Positions within the same physical footprint, the solution significantly reduces the SCPPP, often offsetting the initial investment within a few years through savings on real estate, energy (especially in cold storage), and labor.

3. When and Where to Deploy the 2-Way Pallet Shuttle: Case Studies

3.1 - Ideal Industries for the 2-Way Pallet Shuttle

The 2-Way Pallet Shuttle excels in environments characterized by High Volume and Low SKU count, where bulk storage and rapid handling are paramount:

- Cold Chain Logistics: The system is particularly valuable here, as it minimizes the time human operators and equipment spend in expensive, energy-intensive sub-zero environments.

- Beverage and Food Industry: Handling large quantities of a few product types for seasonal demands.

- Buffer Storage: Acting as an efficient buffer zone between production and shipping.

3.2 - Actual Case Study: Frozen Food Manufacturer

A major frozen food distributor needed to expand capacity without incurring the massive cost of building a new -20°C freezer facility. By implementing the 2-Way Pallet Shuttle system, they were able to: (9)

- Increase Capacity: Added 5,000 new pallet positions within the existing warehouse footprint.

- Improve Safety: Reduced forklift travel time inside the freezer zone by 60%, limiting collision risk and improving operator comfort.

- Achieve LIFO/FIFO: Used different lanes to manage batch production (LIFO) and distribution (FIFO), solving inventory complexity.

3.3 - System Limitations and Considering the 4-Way Alternative

This technology is not a panacea. It struggles in environments requiring immediate access to a wide variety of SKUs or complex sequencing. For those demanding applications, the fully automated and highly flexible 4-Way Pallet Shuttle system—which can move across multiple aisles and levels—is the necessary, albeit more expensive, alternative.

4. Managing the 2-Way Pallet Shuttle’s Lifecycle: Maintenance and WMS Integration

To guarantee long-term system effectiveness, operators must focus on the full lifecycle of the equipment.

4.1 - Critical Preventive Maintenance

The most common issues relate to the batteries and the rails. Establishing a proactive maintenance schedule for battery health and ensuring the racking rails remain clean and structurally sound are crucial steps to prevent unplanned downtime for the shuttle.

4.2 - Seamless Integration with WMS/WCS

The true scaling potential of the technology is unlocked through its integration with a robust WMS (Warehouse Management System) or WCS (Warehouse Control System). This integration allows for:

- Optimized Task Assignment: Automatically assigning storage and retrieval tasks to the correct shuttle and operator.

- Real-Time Inventory: Providing accurate, up-to-the-minute stock visibility within the deep lanes.

5. Summary: Optimizing Your Logistics Strategy with the 2-Way Pallet Shuttle

The 2-Way Pallet Shuttle system stands as a proven, cost-effective solution for enterprises seeking to maximize their existing warehousing footprint and enhance operational safety. It offers a powerful blend of high density and semi-automation, making it an essential tool for competitive logistics. (12)

Don’t let limited space hinder your growth trajectory!

Contact our logistics automation experts today for a tailored consultation. Let us assess your warehouse configuration and design a custom 2-Way Pallet Shuttle solution that guarantees maximized space utilization and rapid ROI.

Recent Blog

-

2-Way Pallet Shuttle System: Maximizing Warehouse Storage Density with Minimal Space

-

Pallet Stacker vs Forklift: Maximize Storage impression

-

Equipment Selection Guide in High Density Warehouse

-

A Practical 5-Step Guide to Choosing the Right Pallet Truck

-

Types of Warehouse Platform Trolleys and Their Uses

Product Enquiry

Fill out the form below and we will contact you as soon as possible.

Visit Our Showroom

Office: F2, TTF Group – Rawang HQ

Business Hour: Monday to Friday 8:00am – 5:35pm | Saturday: 8:30am – 1:00pm

Google Map: Click Here