Standard | 4-Way Pallet Shuttle

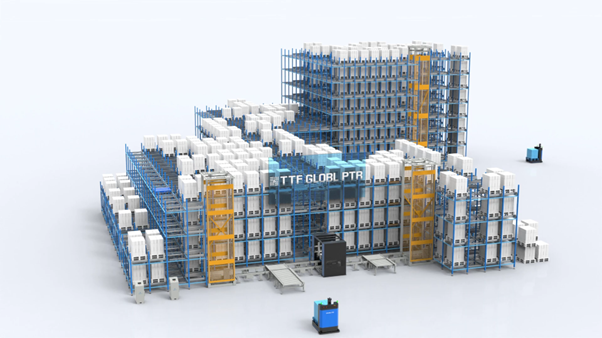

Achieve superior high-density storage with the 4-Way Pallet Shuttle. Its full automation and unrestricted access eliminate the need for wide aisles and maximize pallet throughput.

Standard Model | 4-Way Pallet Shuttle

4-way pallet shuttle is a cutting-edge automated storage and retrieval system (AS/RS) designed for high-density handling of palletized goods. Representing a significant advancement over standard radio shuttles, this technology is the perfect fit for sectors that manage a high volume of inventory with a limited number of Stock Keeping Units (SKUs), such as food & beverage, chemicals, and third-party logistics (3PL) providers.

Key Operational Advantages

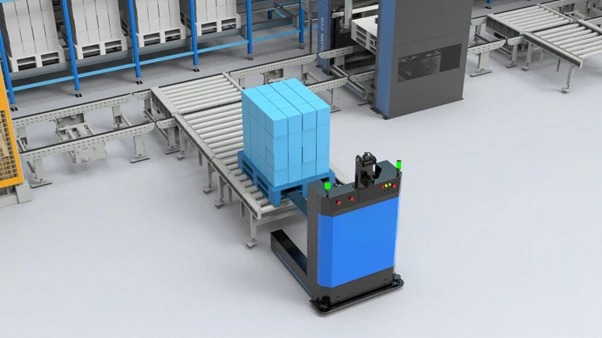

The unique selling point of this system is its four-directional mobility. The shuttle can navigate in all four directions within both the main aisles and storage lanes.

Lane Switching Without Forklifts: This feature allows the shuttle to move across different lanes autonomously, completely eliminating the need for constant forklift intervention.

Reduced Operating Costs: By automating lane transfers, the system drastically cuts down on labor costs and significantly boosts overall warehousing efficiency.

Transformative Business Benefits

Implementing the 4-way pallet shuttle delivers powerful results for your business:

Enhanced Storage Capacity: Achieve a massive increase in storage, often boosting capacity by 3 to 4 times compared to conventional racking systems.

Cost-Effective Solution: Dramatically reduce real estate (land) and personnel costs, offering a highly economical path to growth.

Fully Automatic and Safe: Automated functionality minimizes the risk of product damage and potential injuries to equipment or human operators.

Seamless Integration: Customized Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) are integrated to ensure the system operates smoothly with your existing logistics framework.

Flexible & Scalable: The quantity of shuttles can be easily adjusted to perfectly match your current and future storage capacity demands.

Why Choose Our 4-Way Pallet Shuttle?

INBOUND PROCESS

OUTBOUND PROCESS

4-way pallet shuttle is designed to eliminate common bottlenecks and drive profitability in high-density warehouses.

Maximized ROI & Capacity

Massive Space Increase: By freeing up space previously limited by forklift aisles, the system enables high-density racking designs, boosting storage capacity by approximately 30% to 200%.

Reduced Long-Term Costs: Full automation drastically cuts operational costs by reducing reliance on manual labor, minimizing errors, and allowing for efficient 24/7 operation.

Optimized Throughput

High Operational Efficiency: Seamless WMS/WCS integration intelligently directs pallet movements for significantly faster and more reliable turnaround times.

Eliminates Human Error: Automation solves persistent issues like wrong goods delivery due to picking mistakes and prevents misplaced stock, which causes frustrating inventory discrepancies.

Consistent Speed: Ensures consistently fast picking and retrieval times, removing the variability and delays associated with manual handling.

Why Choose Komada?

GET IN TOUCH WITH US

If you have questions or need more information about our products, feel free to reach out. Our team is ready to assist you with your warehouse needs.