Electric Stacker

Heavy Duty Lifting. Small Space Agility

Komada electric stacker is built for high-density racking and restricted footprints. Engineered for less operating space, Komada pallet stacker electric delivers powerful vertical lifting for high density racking, offering a compact stacker truck solution that maximizes storage capacity without the bulk.

Best Electric Stacker Malaysia

Komada electric stacker is your best choice for local Malaysia warehouses, focusing on high loading efficiency and a rapid ROI (cash back) within just 3 months. Our pallet stackers streamline material handling and maximize vertical storage, effectively reducing labor costs while boosting your daily productivity.

Fully Powered Stacker

Loading Capacity: 1,500KG

Lift Height: 2.7m / 3.0m / 3.6m

Turning Radius: 1,390mm

Feature: Standard High Racking Use

Economic Pro Powered Stacker

Loading Capacity: 1,000kg – 1,500kg

Lift Height: 2.0m / 2.5m / 3.0m

Turning Radius: 1,430mm / 1,480mm

Feature: Adjustable Loading Fork

Double Lifting Powered Stacker

Loading Capacity: 1,500KG

Lift Height: 3.0m / 3.6m

Turning Radius: 1580mm

Feature: Liftable Bottom Fork

Self Lifiting Stacker

Loading Capacity: 1,000KG

Lift Height: 1.5m

Turning Radius: 1300mm

Feature: Strong Loading Power

Fully-Powered Self Lifting Stacker

Loading Capacity: 500KG

Lift Height: 1.3m / 1.5m

Working time: Lifting cycle > 200 times

Feature: Fully Automated Loading & Movement

Semi-Powered Self Lifting Stacker

Loading Capacity: 500KG

Lift Height: 1.3m / 1.5m

Working time: Lifting cycle > 200 times

Feature: Economic Basic Model

All-In-One Ergonomic Control Handle

The Key Part of Effortless Handling

This ergonomic handle integrates all core functions into a single control point for effortless operation. It features intuitive buttons for forward and reverse movement. Precision controls allow for smooth lifting and lowering. For maximum safety, the handle includes a built-in horn and a rear emergency belly button for immediate anti-collision protection.

Strong Power Hydraulic Pump

Core Component of Smooth Lifting

We’re using high-performance DC power hydraulic pump is the heart of the stacker’s lifting system. It delivers consistent, powerful pressure to ensure stable lifting for loads up to 1.5 tons. Built with precision valves and high-quality seals, it provides silent operation and prevents oil leakage. This robust system maximizes work efficiency while minimizing maintenance, ensuring a long-lasting service life for your warehouse.

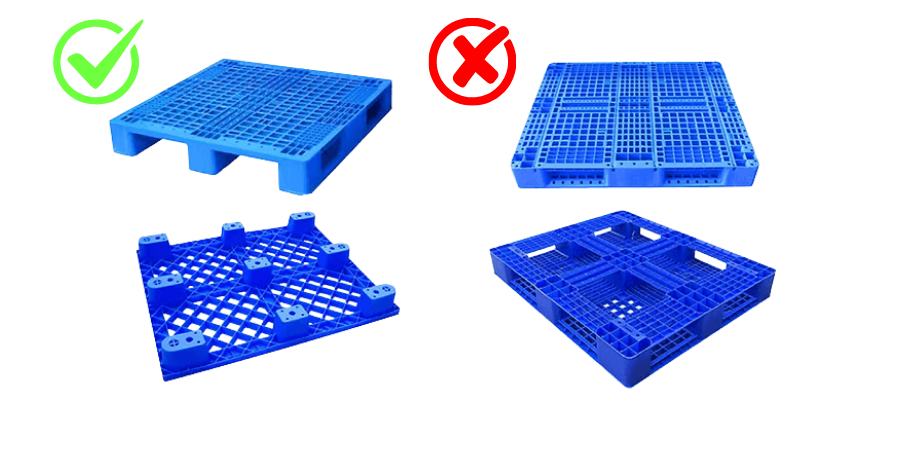

IMPORTANT INFORMATION

Always use Single-sided Pallets to avoid structural damage. Lifting double-sided pallets will cause the bottom boards to snap and break during operation.

Top Picks For Your Warehouse

Pick the most suitable material handling equipment to boost your warehouse efficiency! With our electric stacker series, you’ll achieve cost savings and a high-performance operation flow. Don’t wait, check it out now!

What We Helped Our Clients Achieve

Hear from our satisfied customers about their experiences.

Frequently Asked Questions

What is electric stacker?

Definition of electric stacker

What is the advantage of electric stacker?

Benefit of electric stacker

3. Reduced Operator Strain & Fatigue: Eliminates manual effort for lifting and moving, greatly reducing physical exertion, preventing injuries, and enabling operators to work longer shifts comfortably.

4. Higher Load Capacity & Lift Height: Capable of handling heavier loads and reaching higher shelving heights more safely and efficiently than manual models.

5. Enhanced Safety Features: Often includes advanced safety features like automatic braking, emergency stop buttons, and improved stability for safer operation.

6. Better for Medium to High-Density Storage: Its speed and power make it highly effective for optimizing space in medium-height racking systems and navigating narrow aisles efficiently.

What situation suitable for electric stacker?

Electric stacker usage scenario

2. Busy Operations: Essential where fast stacking and retrieving of pallets directly boosts overall productivity.

3. Focus on Safety & Comfort: A top choice for environments prioritizing worker well-being by reducing strain and fatigue from heavy lifting.

4. Tight Spaces: Designed to work effectively in narrow aisles, helping you maximize your storage area where forklifts might struggle.

Categories You May Interested

If you have any questions or need assistance, please reach out. We’re here to provide the support you need related to our materials handling solutions.