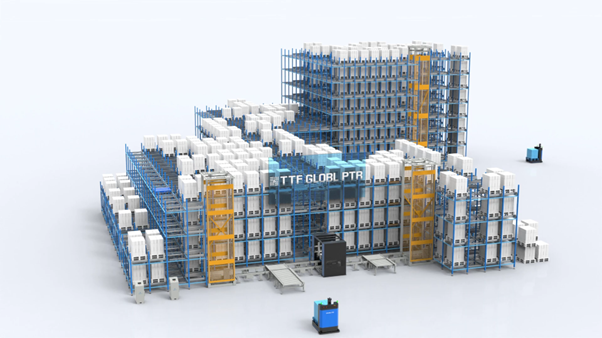

Heavy Duty | 4-Way Pallet Shuttle

Achieve superior high-density storage with Heavy Duty 4-Way Pallet Shuttle. Its full automation and unrestricted access eliminate the need for wide aisles and maximize pallet throughput.

Heavy Duty Model | 4-Way Pallet Shuttle

4-Way Pallet Shuttle is a cutting-edge Automated Storage and Retrieval System (AS/RS). It is specifically engineered for high-density, high-weight handling of palletized goods. This robust technology offers a significant leap forward from standard radio shuttles. It is the ideal solution for sectors managing substantial inventory volumes and limited Stock Keeping Units (SKUs). This includes food & beverage, chemicals, and 3PL providers requiring extra load capacity.

Key Operational Advantages

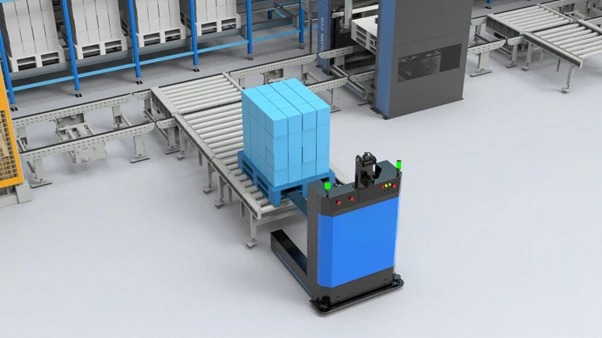

The defining feature of this system is its reliable, four-directional mobility. It maintains this reliability even under heavy loads. The shuttle maneuvers seamlessly in all four directions within both storage and main lanes.

Autonomous Lane Switching: This advanced capability allows the shuttle to transition between different storage lanes autonomously. It completely eliminates the need for constant, risk-prone forklift intervention within the racking structure.

Reduced Operational Costs: The system fully automates lane transfers and handling. This significantly drives down labor expenses. It drastically improves overall warehousing throughput and efficiency.

Transformative Business Benefits

Implementing the heavy-duty 4-way pallet shuttle delivers powerful and dependable results for your enterprise:

Maximized Storage Capacity: Achieve a dramatic increase in storage density. Capacity often boosts by 3 to 4 times compared to less efficient, conventional racking systems.

Economical Path to Growth: This system offers a highly economical solution. It dramatically reduces both real estate (land) requirements and recurring personnel costs.

Fully Automatic and Secure: Automated functionality minimizes product damage risk. It also reduces potential hazards to equipment and operators. This ensures safer handling for heavier inventory.

Seamless Logistics Integration: Custom-designed Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) are expertly integrated. This ensures the shuttle system operates smoothly within your broader supply chain framework.

Flexible and Scalable Solution: The system’s capacity can be easily tailored. This is done by adjusting the quantity of shuttles. It ensures a perfect match for both your current heavy-duty storage demands and future expansion plans.

Why Choose Our Heavy Duty 4-Way Pallet Shuttle?

INBOUND PROCESS

OUTBOUND PROCESS

4-way pallet shuttle is designed to eliminate common bottlenecks and drive profitability in high-density warehouses.

Maximized ROI & Capacity

Massive Space Increase: By freeing up space previously limited by forklift aisles, the system enables high-density racking designs, boosting storage capacity by approximately 30% to 200%.

Reduced Long-Term Costs: Full automation drastically cuts operational costs by reducing reliance on manual labor, minimizing errors, and allowing for efficient 24/7 operation.

Optimized Throughput

High Operational Efficiency: Seamless WMS/WCS integration intelligently directs pallet movements for significantly faster and more reliable turnaround times.

Eliminates Human Error: Automation solves persistent issues like wrong goods delivery due to picking mistakes and prevents misplaced stock, which causes frustrating inventory discrepancies.

Consistent Speed: Ensures consistently fast picking and retrieval times, removing the variability and delays associated with manual handling.

Why Choose Komada?

GET IN TOUCH WITH US

If you have questions or need more information about our products, feel free to reach out. Our team is ready to assist you with your warehouse needs.