Different Types of Warehouse Platform Trolleys and Its Uses

In the fast-paced world of logistics and retail, every detail matters. While large machinery like forklifts get most of the attention, the humble warehouse platform trolley is a crucial tool for daily operations. A smart investment in the right trolley can significantly boost productivity, enhance workplace safety, and prevent costly damages and injuries.

But with so many models available, how do you find the best one for your needs? This comprehensive guide will give you the expert knowledge to choose wisely. We’ll look beyond basic features and dive deep into materials, components, and real-world uses to ensure you make a choice that serves your business for years to come.

1. Two Main Types of Warehouse Platform Trolleys

Platform trolleys are primarily defined by their main material, which affects their performance, durability, and ideal use. Understanding the differences between metal and PVC models is the first and most important step in your decision

A. Metal Platform Trolleys: The Heavy-Duty Workhorse

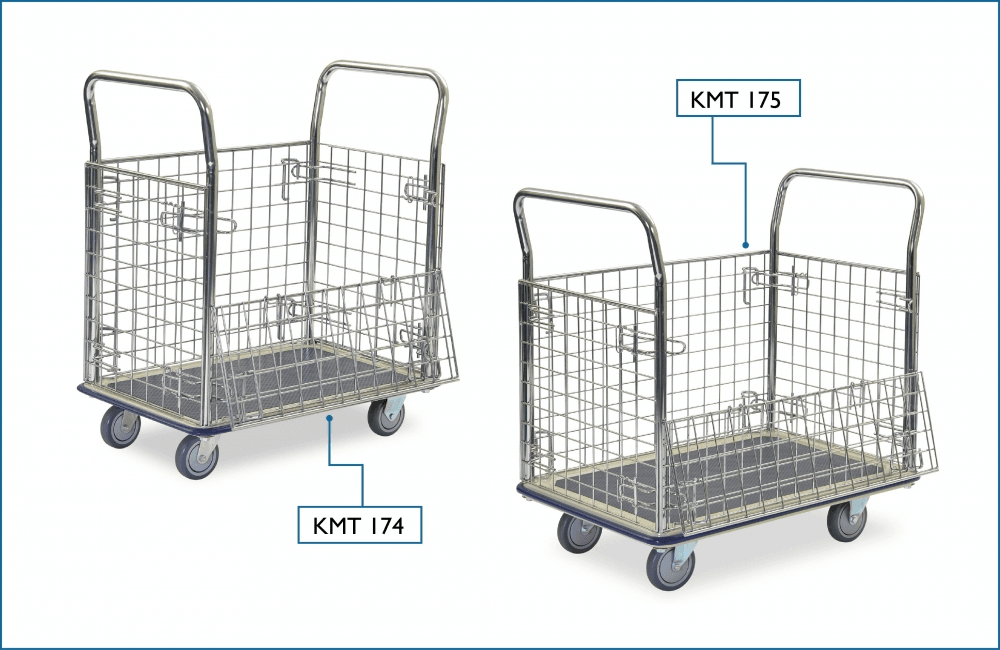

Metal trolleys are the champions of material handling. They are built for extreme durability and heavy-duty tasks, designed to handle the toughest conditions in industrial settings.

- Materials and Build: Made from high-strength steel or reinforced alloy, these trolleys have a robust frame and a solid deck. This construction allows them to carry huge loads and resist impacts. All-welded joints and a powder-coated finish create a long-lasting, rust-resistant structure.

- Load Capacity and Options: This is where metal trolleys truly excel. Their platform trolley load capacity can range from 200kg to over 1000kg. Common options include:

- Single-Level Deck: The standard type, perfect for moving large, heavy, single items.

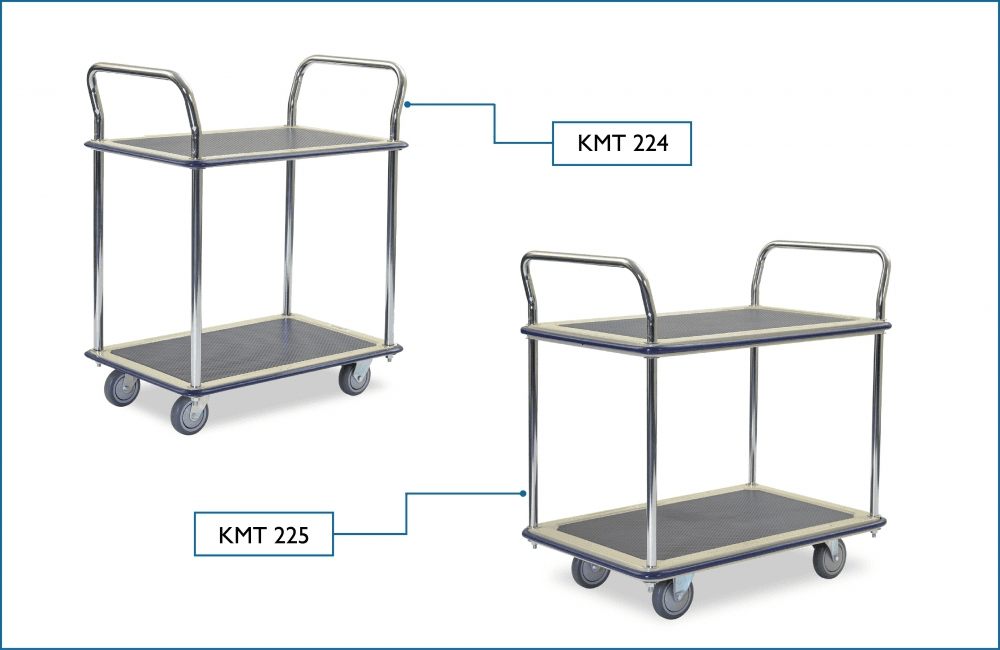

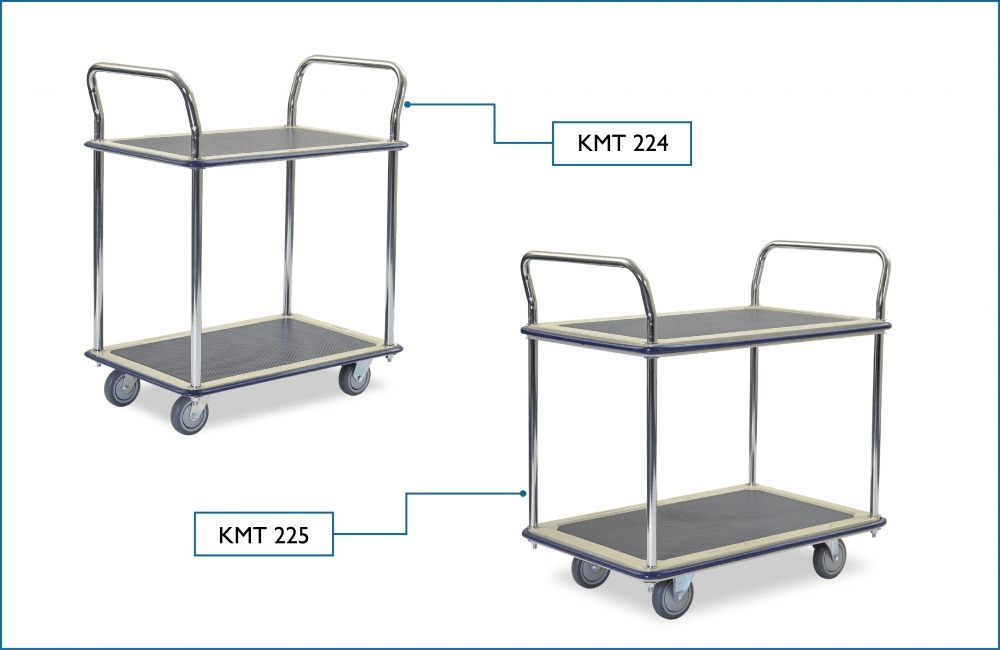

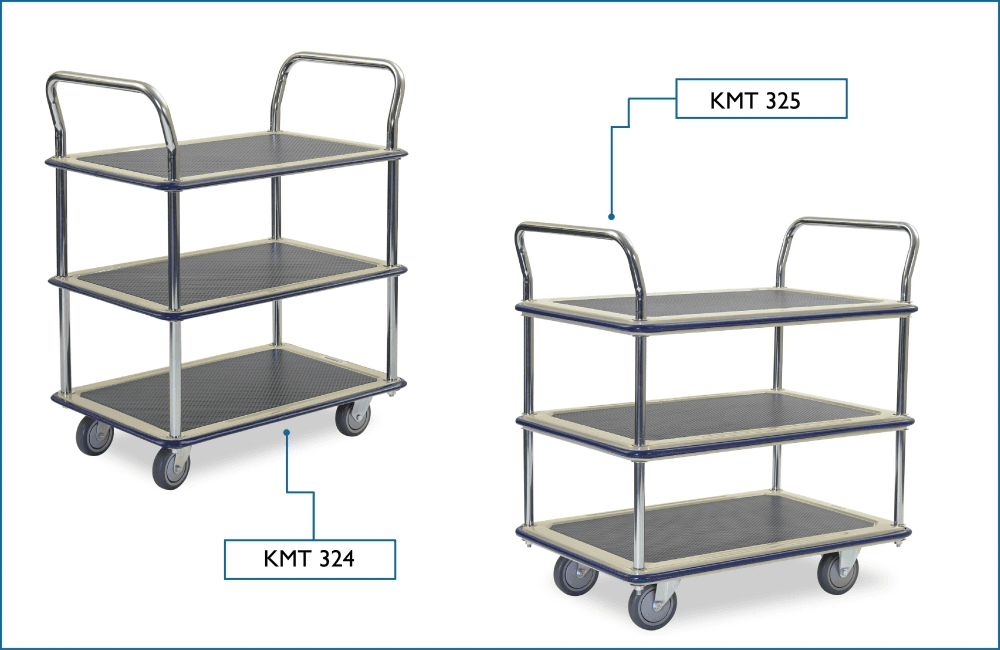

- Double and Triple-Level Decks: These trolleys have multiple shelves, making it easy to organize and transport various items, which can speed up the picking process in a warehouse.

- Best for:

- Manufacturing Plants: A heavy-duty metal trolley with a 500kg capacity is ideal for moving bulky machine parts or finished goods. The rigid frame and tough wheels ensure stability even with uneven weight.

- Construction Sites: Their rugged build and impact resistance make them perfect for moving tools, cement bags, or rebar over rough, debris-filled ground.

- Logistics Centers: In a busy warehouse, metal trolleys are essential for moving large, combined orders to shipping docks, reducing the number of trips needed.

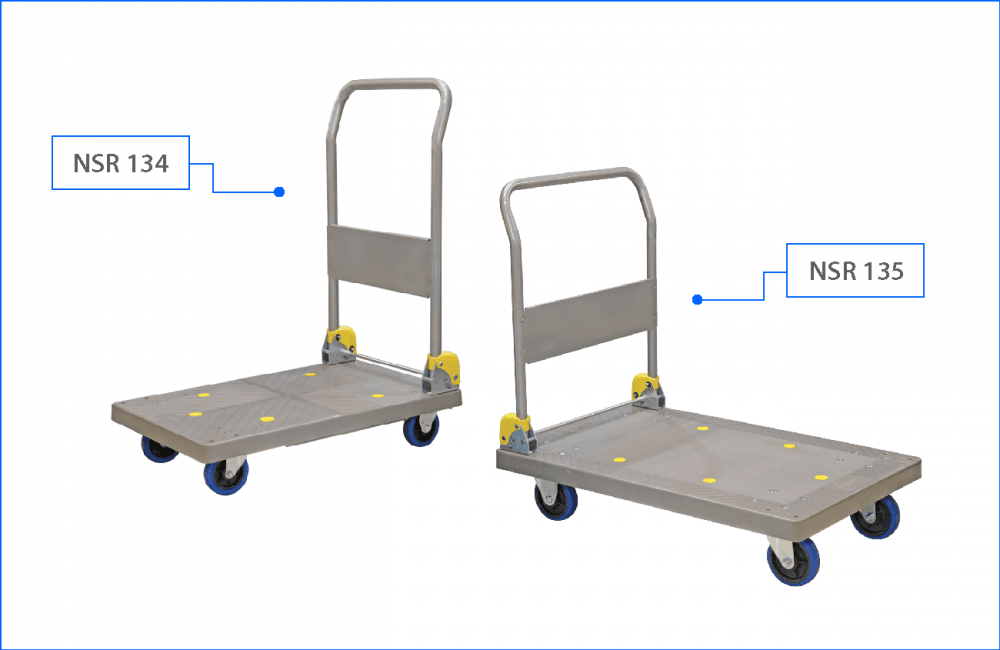

B. PVC Platform Trolleys: The Versatile and Affordable Solution

PVC trolleys are the lighter, more agile version of their metal counterparts. They are the top choice for medium-duty tasks, valued for their great balance of function, affordability, and practical design.

- Materials and Build: These trolleys are made from high-quality polyvinyl chloride, giving them a non-porous, lightweight deck. This material is naturally resistant to corrosion, rust, and chemical spills, making it an excellent choice for certain industries.

- Load Capacity and Options: While their capacity is lower (typically 150kg to 300kg), it’s more than enough for most commercial uses. They also come in different setups:

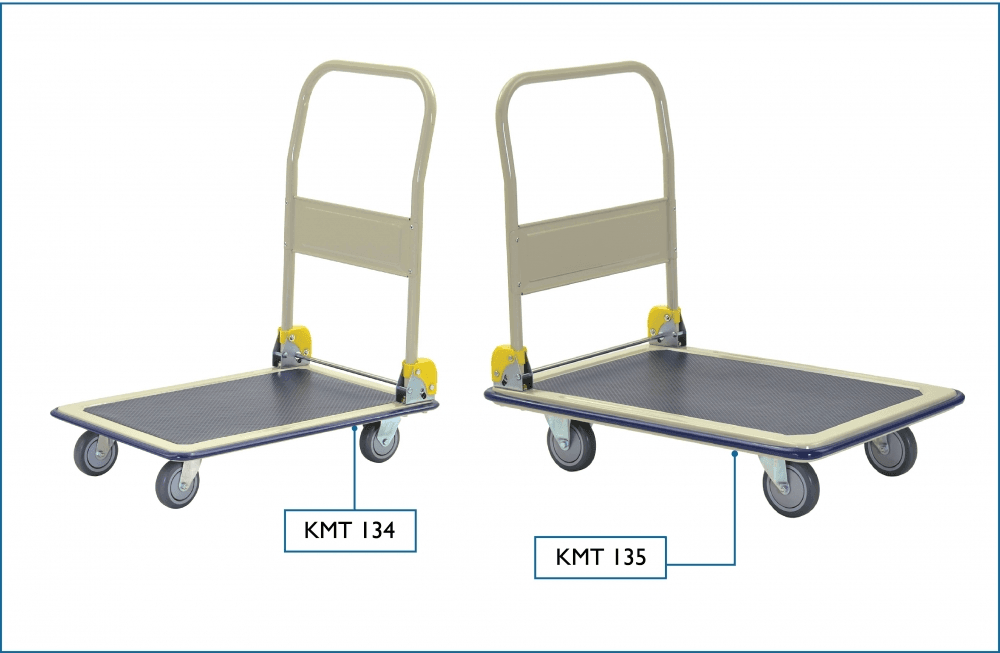

- Foldable Handle Models: A key feature for saving space, as they can be stored compactly in small closets or delivery vehicles.

- Multi-Level Decks: Just like metal trolleys, PVC models offer multi-level options for organizing items, making them very efficient.

- Best for:

- Retail Stores: A retail trolley needs to be quiet and easy to handle. A lightweight PVC model is perfect for restocking shelves and moving inventory without bothering customers.

- Hospitals and Healthcare: Hygiene is a top priority. PVC’s non-porous and easy-to-clean surface makes it an ideal solution for moving medical supplies, linens, and equipment.

- Hospitality and Catering: For carrying food trays, dishes, and cleaning supplies in a hotel or restaurant, a PVC trolley is both a functional and hygienic choice. It resists spills and moisture, ensuring it lasts longer.

2. Key Components That Ensure Quality and Performance In All Types of Warehouse Platform Trolleys

A trolley’s real value isn’t just in its main material—it’s in the quality of its individual parts. A smart buyer knows to look beyond the frame and evaluate the components that truly determine the trolley’s performance, safety, and reliability.

A. Wheels (Casters): The Engine of Your Trolley

The wheels are arguably the most important part, directly affecting everything from how easily the trolley moves to noise levels and floor protection. Understanding the different trolley wheel materials is essential.

- Polyurethane (PU) Wheels: The top choice for most modern warehouses. These wheels are highly durable, non-marking, and provide a quiet, smooth ride. Their high load capacity and excellent resistance to abrasions and chemicals make them ideal for concrete or tiled floors.

- Rubber Wheels: These offer a softer ride and better grip, making them a good option for uneven outdoor surfaces where you need shock absorption. However, they may leave marks and have a lower load capacity than PU.

- Thermoplastic Rubber (TPR) Wheels: A newer material that combines the best of both worlds. TPR wheels are quiet, non-marking, and durable. They offer a cushioned ride similar to rubber but with better rolling and a higher load capacity.

- Nylon Wheels: These are hard and rigid, best for very high load capacities on smooth, hard surfaces. They are a cost-effective option but tend to be noisier and provide less shock absorption.

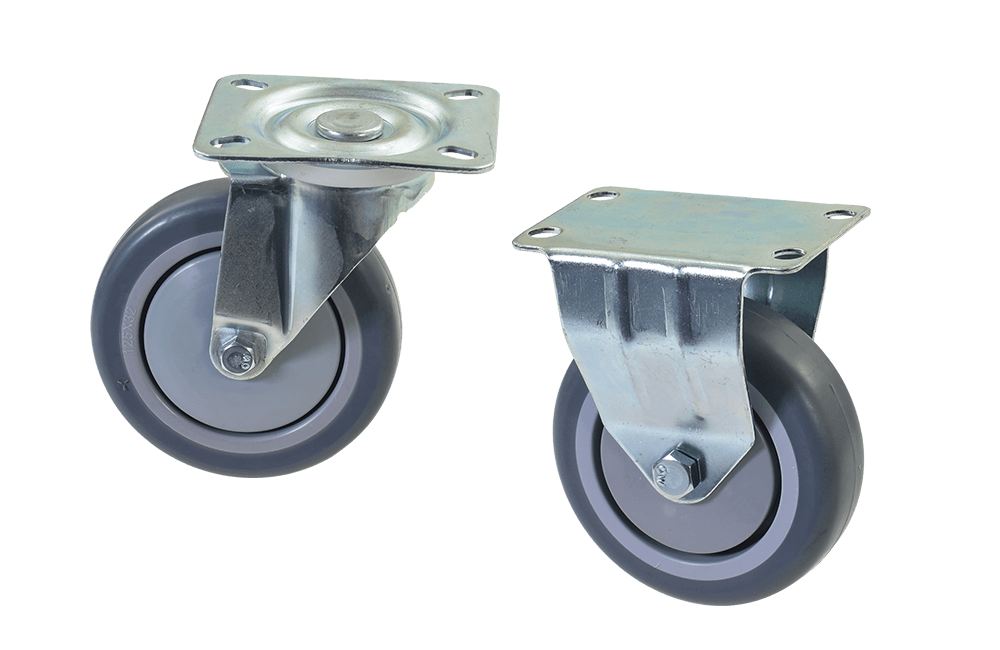

- Caster Types:

- Swivel Casters: Allow 360-degree rotation, providing maximum maneuverability in tight spaces.

- Fixed Casters: Keep the wheel in a straight-line position, offering stability and control for moving over long distances. A common setup is two fixed and two swivel casters for a good balance.

- Swivel Casters: Allow 360-degree rotation, providing maximum maneuverability in tight spaces.

B. Braking Systems: A Key to Workplace Safety

A reliable braking system is not a luxury—it’s a necessity. It is your last defense against accidents, especially when operating on inclines or when loading and unloading.

- Foot-Operated Brakes: The most common type, where a simple foot pedal locks a single wheel, stopping the trolley from rolling.

- Total Lock Brakes: An advanced system that locks both the wheel and the swivel mechanism, preventing the trolley from moving in any direction. This is highly recommended for use on slopes or when you need precise positioning.

- Central Braking System: Often found on high-end models, this system allows a single pedal to lock all wheels at once, providing maximum stability with minimal effort.

3. Maintenance and Safety Best Practices For All Types of Warehouse Platform Trolley

A high-quality trolley is a valuable asset, but its lifespan and safety also depend on proper use and maintenance.

- Maintenance Tips:

- Regular Cleaning: A simple wipe-down can prevent dirt and debris from building up, especially on the wheels and axle.

- Lubrication: Periodically lubricating the caster bearings ensures smooth, quiet operation and extends their life.

- Inspection: Routinely check for loose bolts, damaged wheels, or signs of frame fatigue. Fixing these issues early can prevent a small problem from becoming a major one.

- Regular Cleaning: A simple wipe-down can prevent dirt and debris from building up, especially on the wheels and axle.

- Safety Practices:

- Never Exceed Load Capacity: Always stick to the manufacturer’s specified platform trolley load capacity. Going over this limit can lead to structural failure and serious injury.

- Secure the Load: Use straps or anti-slip mats to ensure the load is stable and won’t shift during transport.

- Use the Brakes: Always engage the braking system when the trolley is stationary, especially on a slope or when you’re loading or unloading.

- Never Exceed Load Capacity: Always stick to the manufacturer’s specified platform trolley load capacity. Going over this limit can lead to structural failure and serious injury.

4. Your Three-Step Buying the correct types of warehouse platform trolley

With all this information, making the final choice can still feel overwhelming. Follow this simple three-step process to confidently select a model that fits your needs.

- Assess Your Needs: Start by defining your key requirements. What’s the maximum weight you’ll be moving? What’s your work environment like (e.g., wet, oily, smooth, or rough floors)? What are your priorities (e.g., durability, portability, or cost)?

- Match the Trolley to Your Use: Use this guide to match your needs to the right trolley type. If you’re moving heavy items in a rugged factory, a heavy-duty metal trolley is the only safe choice. For daily stock management in a quiet retail store, a lightweight PVC trolley is the smarter, more economical option.

- Consider the Components: Look past the frame and evaluate the quality of the wheels and braking system. These are the components that will ultimately decide the trolley’s long-term performance and reliability.

5. Need Help Choosing the Right Types of Warehouse Platform Trolley?

There are many types of warehouse platform trolleys on the market, with some brands focusing on competitive pricing and others on quality. If you have a local business in Malaysia, Komada is an excellent choice.

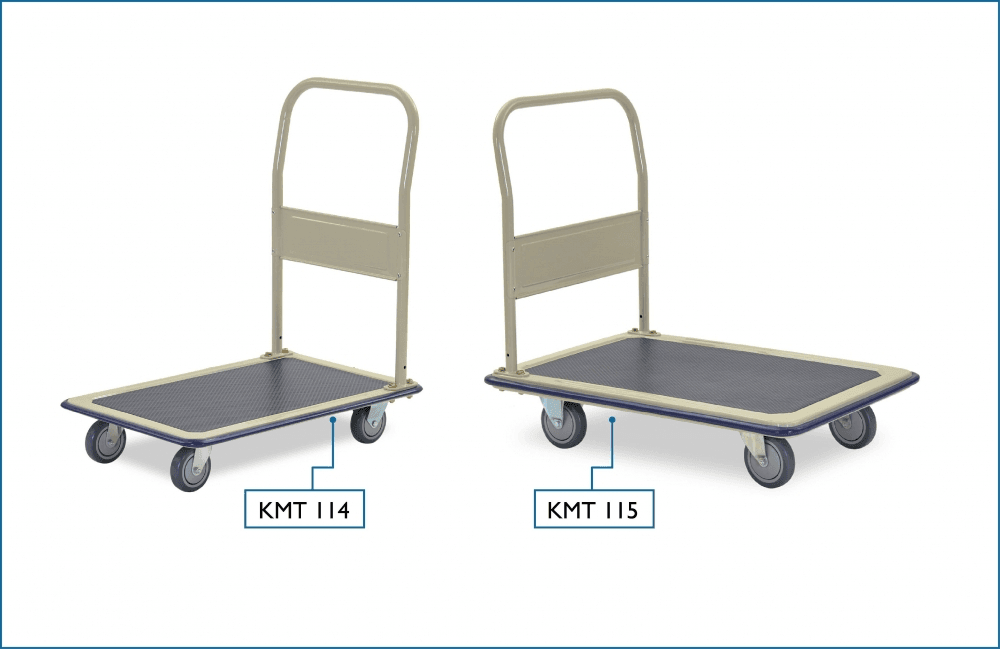

Komada is a leading local supplier in Malaysia, based in Rawang, Selangor, with over 20 years of experience in the material handling industry. What makes us stand out? Komada balances premium quality and affordable prices, providing you with high-end equipment like platform trolleys without the hefty cost. We offer both PVC and metal trolleys, with options for up to three tiers, single and double handles, and a load capacity of up to 500kg to meet most industry needs.

We don’t just focus on products; we provide excellent service to all our clients. For instance, we offer Warehouse Consultation—a free service where you can get a clear and detailed solution for your material handling issues. We also offer Fast Delivery and our team ensures your product arrives in good condition. Plus, with our After-Sales Maintenance and a warranty of up to 12 months, you don’t have to worry about your equipment breaking down.

Conclusion: A Strategic Investment for Your Business

Choosing the right types of warehouse platform trolleys is a key investment that directly impacts your business’s efficiency and bottom line. By looking at the materials, components, and intended use, you can confidently select a model that will serve your business reliably for years to come. This guide has given you the knowledge to make an expert choice.

For personalized advice or to see how Komada can help you find the perfect trolley for your specific needs, please feel free to contact us today!

Recent Blog

-

2-Way Pallet Shuttle System: Maximizing Warehouse Storage Density with Minimal Space

-

Pallet Stacker vs Forklift: Maximize Storage impression

-

Equipment Selection Guide in High Density Warehouse

-

A Practical 5-Step Guide to Choosing the Right Pallet Truck

-

Types of Warehouse Platform Trolleys and Their Uses

Product Enquiry

Fill out the form below and we will contact you as soon as possible.

Visit Our Showroom

Office: F2, TTF Group – Rawang HQ

Business Hour: Monday to Friday 8:00am – 5:35pm | Saturday: 8:30am – 1:00pm

Google Map: Click Here